Using a duct collector in Ontario is a great way to improve the quality of the air in your shop. However, many people may not be aware of the additional benefits of dust collectors. VeriCUT offers high-quality dust collectors and proudly serves businesses across North America. This blog will explain how dust collectors work and will provide tips in regards to how to choose the right one for your needs.

What Are Dust Collectors?

Dust collectors in Ontario can improve the quality of the air in your shop during mechanical, metalworking, woodworking, and commercial and industrial processes. More specifically, the VeriCUT system removes fine dust particles from the air, as well as other airborne particles and impurities by drawing them back into the table.

The downdraft cutting tables have special slotted air ducts in them, which can help you efficiently extract the particles from the air. When the cutting machine is idle, the speed of the motor in the fan of the dust collector will be reduced. With the wireless connection, the pre-programmed instructions will look at the machine’s variables and report both the stats and the machine’s status. This can result in an 80 percent reduction in heat and electricity loss.

What Companies Use Dust Collector Systems for

Previous studies have shown that fume and dust-producing operations do not achieve more than 30% of operating time. On the other hand, your dust collection system may operate around the clock. That means that with a traditional system, you are wasting as much as 80% of your electricity.

However, with the VeriCUT system, the motor that controls the dust is either shut down or scaled back when it’s not in use. This allows you to control both your costs and the parameters, saving up to thousands of dollars each year.

You can usually see a return on your investment in approximately seven and a half months. The types of businesses that can benefit from a dust collector in ontario include:

- Woodworking Shops

- Agricultural, Food, and Chemical Companies

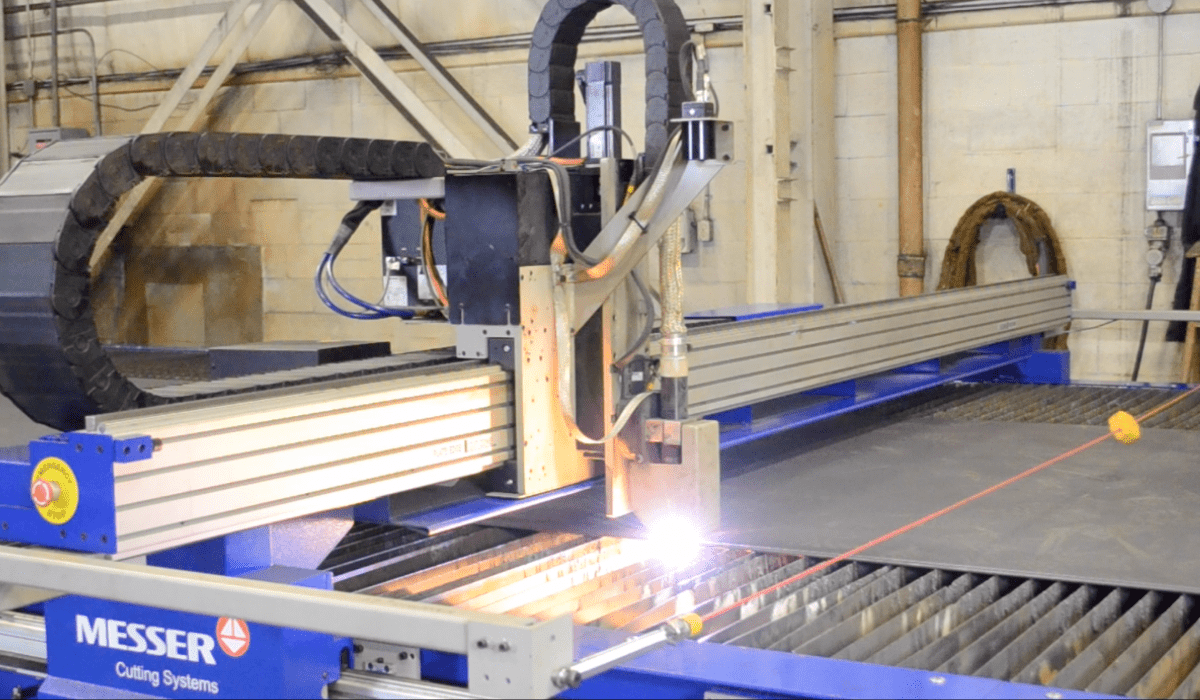

- Companies That Use Plasma- and Laser-Cutting Tables

- Pharmaceutical Businesses

- Businesses That Use Any Other Process That Produces Fumes or Dust

About Our President

Paul Rak is the president of VeriForm Inc., which is a metal fabrication company established more than two decades ago. Rak has a Bachelor of Science in biology from the University of Western Ontario. He also attended the University of Waterloo to learn about business management. He is a member of the Regional Sustainability Initiative in the Waterloo Region and often speaks on topics that relate to sustainability for different companies as an expert on going green.

Rak founded VeriCUT in 2001 with a focus on creating downdraft tables for the water-, laser-, and plasma-cutting sectors.

Why Choose VeriCUT?

VeriCUT is passionate about providing equipment that will improve the quality of air in your shop and productivity while lower operating costs. VeriCUT created the Crossflow Downdraft Cutting Table to eliminate dangerous dust and smoke during the plate cutting process. It is currently one of the top tables in North America for eliminating smoke and dust.

VeriCUT also has a commitment to being an accessible company. The company has made it a priority to implement policies and practices for people with disabilities. They have a special hiring process that accommodates candidates with disabilities during interviews, the selection period, onboarding and training.

While the company’s physical location is in Kitchener, Ontario, VeriCUT, Inc. is proudly serving businesses across North America. If you’re interested in learning more about VeriCUT, please contact us today. Our experienced and knowledgeable team will be happy to provide you with more information about VeriCUT, our products, services and dust collectors.

August 12, 2020