It can be hard to maintain the air quality in your machine shop. Therefore, you may want to consider purchasing a professional-grade customized downdraft table from VeriCUT. A high-quality industrial downdraft table equipped with a shop dust collector will address and remedy your shop’s issues with poor air quality.

How Do They Work?

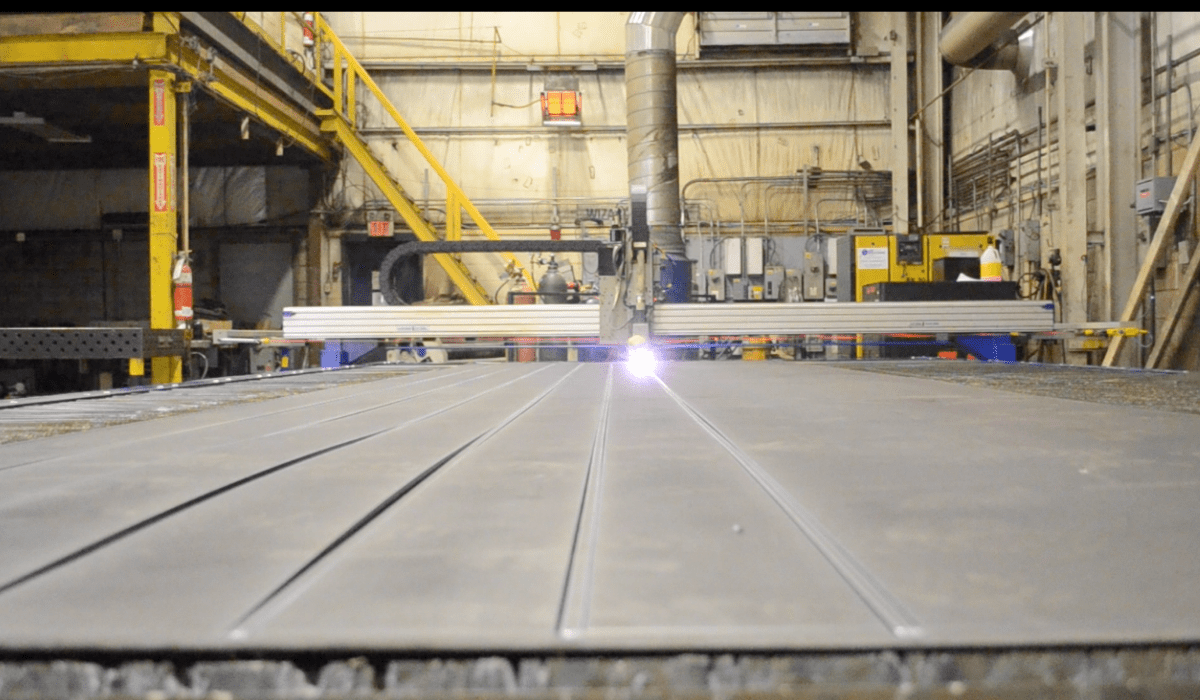

VeriCUT downdraft cutting tables pull the smoke, dust and contaminants in the air down and away from your breathing space. The duct has the same air draw, no matter where the cutting torch is across the width or length of the table. The table can pull in and remove smoke from as far as two to three feet above. As a result, the table removes the hazardous smoke and particles that are generated near your source and avoids contaminating your shop.

What You Can Use Them For

Industrial downdraft tables are perfect for removing both fumes and dust from your air during many or your shop’s different applications. These include, but are not limited to, polishing, grinding, cutting, welding, and sanding your metal products. You can use them when during applications as:

- Sanding: It is now easier for you to achieve a smooth finish on your products without causing fine dust particles to spread throughout your shop.

- Welding: You can use an industrial downdraft table for applications that are more involved, such as MIG and TIG.

- Deburring: This is beneficial when using abrasives to finish or polish materials that have been fabricated.

- Grinding: This is done to remove bits of refuse from your plastic and metal grinding.

- Mixing: Shop dust collectors are used when mixing in order to stop granules and powders from escaping into the air.

- Cutting: The shop dust collector is perfect for plasma cutting and can improve your health and safety by removing the dust and fumes released into the air that you’re breathing in.

Benefits of Using an Industrial Downdraft Table

When you are soldering, welding, painting, etc. it is important that you do not inhale the resulting particles. Otherwise, you may experience health effects such as, headaches, dizziness, and in some more severe cases, permanent lung damage. Using an industrial downdraft table can help you capture and eliminate toxic gases, fumes, smoke, and fine dust particles right at the cutting source.

Fine dust particles are nearly impossible to see without using magnification. Therefore, you may be unaware of how much dust is polluting the air quality in your shop. It is important to remember that dust can still enter your body if you are wearing a mask and it can cause many acute or chronic health conditions for those who inhale dust on a regular basis.

As fine dust particles settle in your lungs, they can impair the functionality of your lungs. Eventually, this can cause inflammation and scarred tissue within your body. The effects are particularly problematic when the dust enters your bloodstream through your lungs and affects your brain, kidneys, and liver, which will undoubtedly lead to chronic and acute health conditions. If left untreated, you may require medical attention and in many cases the damage cannot be reversed.

VeriCUT’s industrial downdraft tables achieve significantly superior productivity and cost savings by utilizing a zone-by-zone ducting design that provides localized smoke removal right at the cutting source. This means that the dust collection system is only drawing smoke in from the area being used, resulting in:

- Lower air make-up costs

- Higher dust recovery rates

- Smaller dust collection system required

- Better ROI on your equipment

In addition, because the industrial downdraft tables are 100% mechanical, maintenance and repairs are rarely required.

Closing Thoughts

The VeriCUT industrial downdraft tables are arguably the most energy-efficient tables currently on the market. If you’re interested in learning more about industrial downdraft tables, or are thinking about purchasing one for your shop, please contact VeriCUT today.

August 22, 2020