If you own or manage a facility that generates combustible dust, dust collection is a fundamental consideration. It doesn’t matter whether you run a large commercial metalworking operation or a smaller shop where you pursue a woodworking hobby: once dust accumulates, it can become dangerous. The solution: a professional dust collection system.

There are different types of dust safety solutions out there, from baghouses and cyclones to downdraft tables that filter smoke and particles created by grinding, welding, and polishing operations. In this blog, the team at VeriCUT will introduce and explain the important considerations in buying a professional dust collection system that works for you.

What to look for

When you’re on the market for a dust collector, there are six considerations that should inform your final purchase.

- It must be able to capture different types of dust. Not all dust is powder-fine. Some processing operations produce larger particles that still present a combustion hazard. You need to invest in a system that captures all types and sizes of dust equally effectively.

- It should be easy to maintain. While advanced problems should only be addressed by the pros, a good dust collector needs to be easy for you and your team to clean, maintain, and troubleshoot. A system that’s too complicated can also be too expensive to keep in efficient working order.

- It should be compatible with your process. Not all professional dust collection systems operate the same way. For example, cyclones separate larger particles from the airstream, so they are recommended for applications that produce bigger debris, such as wood chips. Downdraft cutting tables, on the other hand, have built-in ventilation systems that capture and draw fumes, smoke and/or dust away from the work area, protecting both employees and the materials being worked on.

- It should be energy-efficient. Most dust collection systems operate 24-7, but studies have shown that dust and fume-producing operations rarely account for over 30% of your facility’s operating time. The best machines will let you scale back the variable motor on shut down and leave it off until it’s needed again.

The VeriCUT advantage

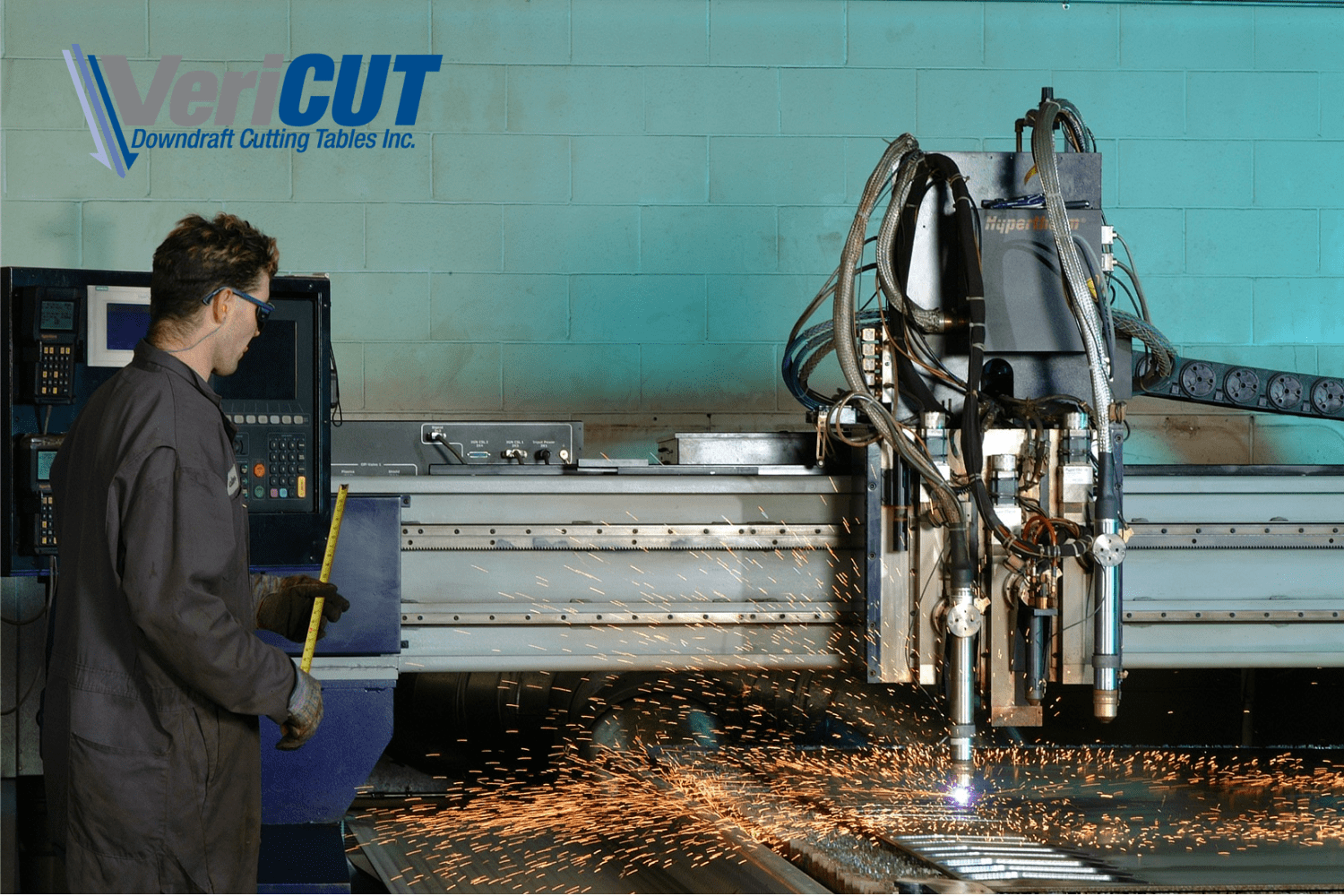

If you want to invest in a professional dust collection system with a proven track record for energy-efficiency and reliable performance, VeriCUT will design, build, and install a machine that removes smoke and dust during laser, plasma, and oxy-acetylene cutting operations. Our proprietary Crossflow™ Downdraft Cutting Table clears the work area of contaminants, improving worker safety and productivity while lowering your energy costs and dust accumulation levels. The mechanical design also means more uptime and fewer costly repairs.

Features and advantages include:

- A dust recovery rate of up to 99%.

- A smoke draw system that evenly pulls in smoke across the full width of the table. The ducting has been specially engineered to have the same feet per minute air pull no matter where the cutting torch is working on the table.

- Smoke can be drawn back down from as high as two or three feet across the table, helping to ensure that your facility does not become polluted by smoke and dust.

- A zone-by-zone ducting design that saves you a lot in air take-up costs. The duct doors are laser-cut and precision-fitted to improve air draw efficiency.

- The dust control variable motor automatically scales back when not in use, preventing unnecessary electrical costs.

We understand that every client has unique dust and fume collection requirements for their space, which is why our downdraft cutting tables are custom designed and built. For added compatibility, we can do a retrofit on existing installations, make future expansion easy and cost-effective by using bolt-in-place, fully self-contained table modules, and offer optional features like under-the-table hidden caterpillar tracks for tight spaces.

Contact a trusted Canadian dust collection system provider

At VeriCUT, we have a national reputation for supplying unique and innovative professional dust collection systems for all industries, needs, and budgets. Our professional team will engineer a safe and reliable solution based on your business type, its processes, and the properties of the dust handled. Our systems are energy-efficient, require little to no repairs, and designed to make your facility a safer place to work. To schedule a consultation to discuss your dust collection needs, please contact VeriCUT Inc.

September 23, 2020